THE PRODUCTION PROCESS OPTIMIZATION IN A STEEL PLANT

Feralpi Group – Lonato, Brescia (IT)

PDF versione italianaPROJECT DESCRIPTION

KEYWORDS: Steel plants | Volumes computation | Stockpiles | Heron | 3D Mapping

Feralpi has set itself the goal of introducing advanced systems to monitor and verify the flows of raw materials and by-products of the steel mill, in order to optimize its production process.

Feralpi has chosen HERON technology because it fits their different needs. On one hand, the need to periodically obtain the volumes of the scrap stockpiles stored on a large area of the plant; on the other hand, the need for a high speed of scanning and results delivery, ensuring the required accuracy.

The project involves a monthly survey of the material stockpiles with HERON portable laser scanner technology.

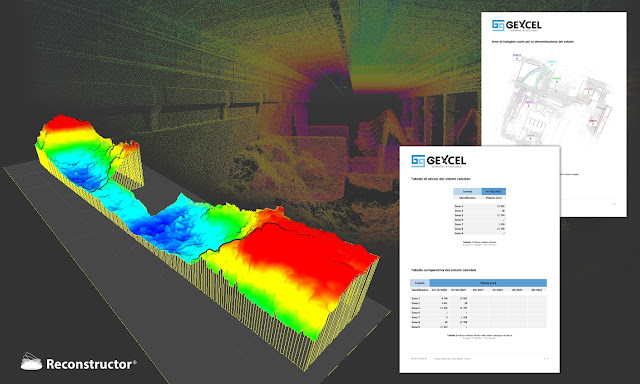

During the 3D modelling phase, the stockpiles are isolated from the structural elements of the plant to define their volume.

The day after the measurement, a technical report with the measurements of the overall volumes is provided to Feralpi.

Thanks to this technological improvement, Feralpi is experimenting with a more efficient approach to the management of raw materials at low costs.

NEEDS AND GOALS

- To monitor and verify the flows of raw materials and by-products of steelworks by using advanced systems.

- To optimize the production process.

« Thanks to HERON technology we are able to map our material parks in a short time and with high precision. »

Gianpaolo Foglio | Head of Steelworks at Feralpi Siderurgica S.p.A.

- Fast and simple mapping procedures easy to reproduce

- Fast mapping of large stockpiles

- No impact on daily production activities

- Fast volumes computation

- Centimetre level accuracy

- Costs reduction

- Production efficiency improvement

- Usable for mapping different type of sites (steel plants as well as buildings)

RESULTS

- Stockpiles 3D modelling

- Volumes computation

TECHNICAL DETAILS

- SURVEYING SYSTEM: HERON portable mapping system

- SURVEYING TIME: about 1 h for 18.300 m2

- PROCESSING SOFTWARE: HERON Desktop - Reconstructor

- DATA PROCESSING TIME: half working day

To carry out the work, Feralpi Group makes use of the HERON rental service with the operator, data processing and delivery of results.

ABOUT

The Feralpi Group is one of Europe's leading steel manufacturers. It offers innovative and sustainable answers to the steel supply chains thanks to a diversified and vertical business.

9:16:00 am

Tags :

case studies

,

gexcel

,

heron

,

reconstructor

,

stockpile

Subscribe by Email

Follow Updates Articles from This Blog via Email

No Comments