Home

/

Posts Filed Under

mining

Showing posts with label mining. Show all posts

25 Jul 2019

16 Oct 2018

HERON SUCCESS CASE — 3D MAPPING OF UNDERGROUND MINES

3D SURVEYING OF UNDERGROUND FIELDS FOR GEOLOGICAL ANALYSIS Abandoned mines of Paglio (Dossena, BG), Italy

PDF versione italiana

KEYWORDS: Mining | Underground | HERON | 3D Mapping

|

|

| Dossena's mine survey activities |

NEEDS AND GOALS

- Geometric acquisition of underground environments at various levels of depth in a disused mine.

- Production of georeferenced data for subsequent assessments of geological stability of the site.

Underground mines represent an important challenge for geometric surveying activities. The narrow spaces, sudden gradients, the presence of water, dust and humidity, the uneven paving and the impossibility to receive the GNSS signal often make it impossible to apply the traditional survey techniques. At Paglio's abandoned mines, thanks to the use of HERON system, it was possible to penetrate the entrails of the mines and measure the extent of underground environments, providing a mesh model of the entire structure.

« The rugged backpack of HERON MS-1 made it possible to easily move around the different environments, even where the presence of water and dust could have hindered the success of the work »

Stefano Cantoni | Surveyor, University of Brescia

|

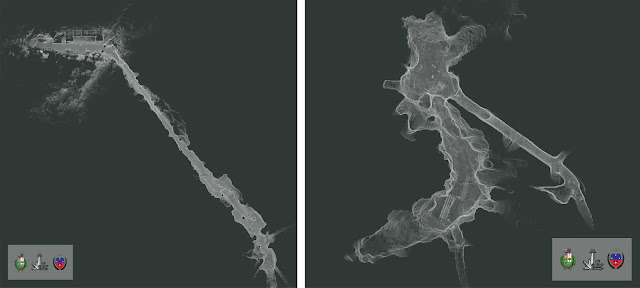

| HERON point cloud aligned with a georeferenced static scan |

RESULTS

The carried out activities are part of the studies and works aimed at the recovery of the former fluorite mines of Paglio Pignolino in the Municipality of Dossena (BG) for fruition, tourism and scientific purposes. The described case saw the use of the HERON system in its rugged version called MS (Mining Survey), designed to operate effectively in aggressive environments such as deep mines. The data processing has produced 3 plants of the mine almost in real-time, thanks to the HERON Desktop software. The 3D point cloud generated by the instrument was subsequently transformed into a mesh model with the JRC 3D Reconstructor software.

The interventions are commissioned and coordinated by the Municipal Administration, with the support of the Dossena Mining Association, for the management of the site, and of the geological associated study of Spada di Ranica for the study and design activities, with the collaboration of the University of Brescia.

- 3D point cloud model

- 2D map (blueprint)

- Surfaces model (mesh) of surveyed environments

- Profiles and sections

- Volumes and areas

The carried out activities are part of the studies and works aimed at the recovery of the former fluorite mines of Paglio Pignolino in the Municipality of Dossena (BG) for fruition, tourism and scientific purposes. The described case saw the use of the HERON system in its rugged version called MS (Mining Survey), designed to operate effectively in aggressive environments such as deep mines. The data processing has produced 3 plants of the mine almost in real-time, thanks to the HERON Desktop software. The 3D point cloud generated by the instrument was subsequently transformed into a mesh model with the JRC 3D Reconstructor software.

|

| Planimetric view of different deep mining levels |

The interventions are commissioned and coordinated by the Municipal Administration, with the support of the Dossena Mining Association, for the management of the site, and of the geological associated study of Spada di Ranica for the study and design activities, with the collaboration of the University of Brescia.

HERON MS-1 MAIN BENEFITS

- Quick mapping of internal environments, without the use of targets for merging 3D scans.

- Rapid detection (acquisition time equals walking speed).

- Sturdy equipment suitable for aggressive environments.

- Possibility to georeference the surveyed model.

- Real-time control of the surveying process through 3D visualization of the acquired data.

TECHNICAL DETAILS

- SURVEYING SYSTEM: HERON MS-1

- SURVEYING TIME: 2 hours for a path of 1,255 m and for georeferencing activities (through detection of spheres previously georeferenced with the total station)

- PROCESSING SOFTWARE: HERON Desktop and JRC 3D Reconstructor®

- PROCESSING TIME: 8 hours

9 Jul 2018

HERON SUCCESS CASE — UNDERGROUND MINING

3D SCANNING OF AN OLD MINE Zhejiang Province (China)

PROJECT DESCRIPTION

KEYWORDS: Mining | Underground | HERON | 3D Mapping

The surveying of an underground mine is difficult for two orders of problems: the complicated and dark tunnels environment and the underground depth where GPS or GNSS signal can't be reached.

The Aurantech company has faced this problem in an old underground mine site, in Zhejiang and thanks to the HERON wearable mobile mapping system the procedure for data collection was not only possible but also efficient.

After pre-processed the surveying acquisitions and filtered the noise, it has been possible to build the surface model of the tunnel, based on the required parameters, with a global accuracy of 10 cm.

The data extraction has been made with JRC 3D Reconstructor software. First of all, the data have been aligned via the automatic registration and bundle adjustment software's functions. Then, the cross-sections have been easily generated and volume and surface areas computed on the 3D model. Finally, the 3D model was easily exported to third-party applications using one of the most common data interchange formats.

The Aurantech company has faced this problem in an old underground mine site, in Zhejiang and thanks to the HERON wearable mobile mapping system the procedure for data collection was not only possible but also efficient.

After pre-processed the surveying acquisitions and filtered the noise, it has been possible to build the surface model of the tunnel, based on the required parameters, with a global accuracy of 10 cm.

The data extraction has been made with JRC 3D Reconstructor software. First of all, the data have been aligned via the automatic registration and bundle adjustment software's functions. Then, the cross-sections have been easily generated and volume and surface areas computed on the 3D model. Finally, the 3D model was easily exported to third-party applications using one of the most common data interchange formats.

|

| Fig 1. The operator with HERON AC-1 during the surveying activities in the underground mine Fig 2. HERON point cloud model of the underground mine with the path |

|

| Fig 3. HERON 3D mesh model |

« What we had to do was just to set up some control points using a total station and then simply walk with HERON. Software and hardware made the work easier and supplied us with a complete solution. HERON is a reliable, simple and high-performance 3D solution »Sherry Wang

AURANTECH | Commercial Manager

NEEDS AND GOALS

- Generate a precise map of an old tunnel where tripod laser scanners or GPS cannot be used.

- Build a measurable 3D model of the underground mine starting from the 3D point cloud.

RESULTS

- 3D point cloud model

- Depth calculation

- Area calculation

- Cross-sections

- Volume calculation

|

| Fig 4. CAD environment: cross-sections of the HERON point cloud model |

HERON AC-1 MAIN BENEFITS

- Work without GPS or GNSS sensors

- The precision of final results

- Management of wide and different data

TECHNICAL DETAILS

- SURVEYING SYSTEM: HERON AC-1 and total station

- SURVEYING AREA: 250,000 sqm abandoned mine

- SURVEYING TIME: 6 hours

- PROCESSING SOFTWARE: HERON Desktop and JRC 3D Reconstructor

- PROCESSING TIME: 18 hours

ABOUT

Aurantech | www.aurantech.com

Aurantech is a high-tech company situated in Shangai (China) featured to provide complete 3D solutions; highly experienced in 3D project services from 3D data collection, 3D data processing to the 3D information management system for final customers.

Etichette:

3d,

case studies,

gexcel,

heron,

jrc 3d reconstructor,

mining

Subscribe to:

Comments (Atom)